No products in the cart.

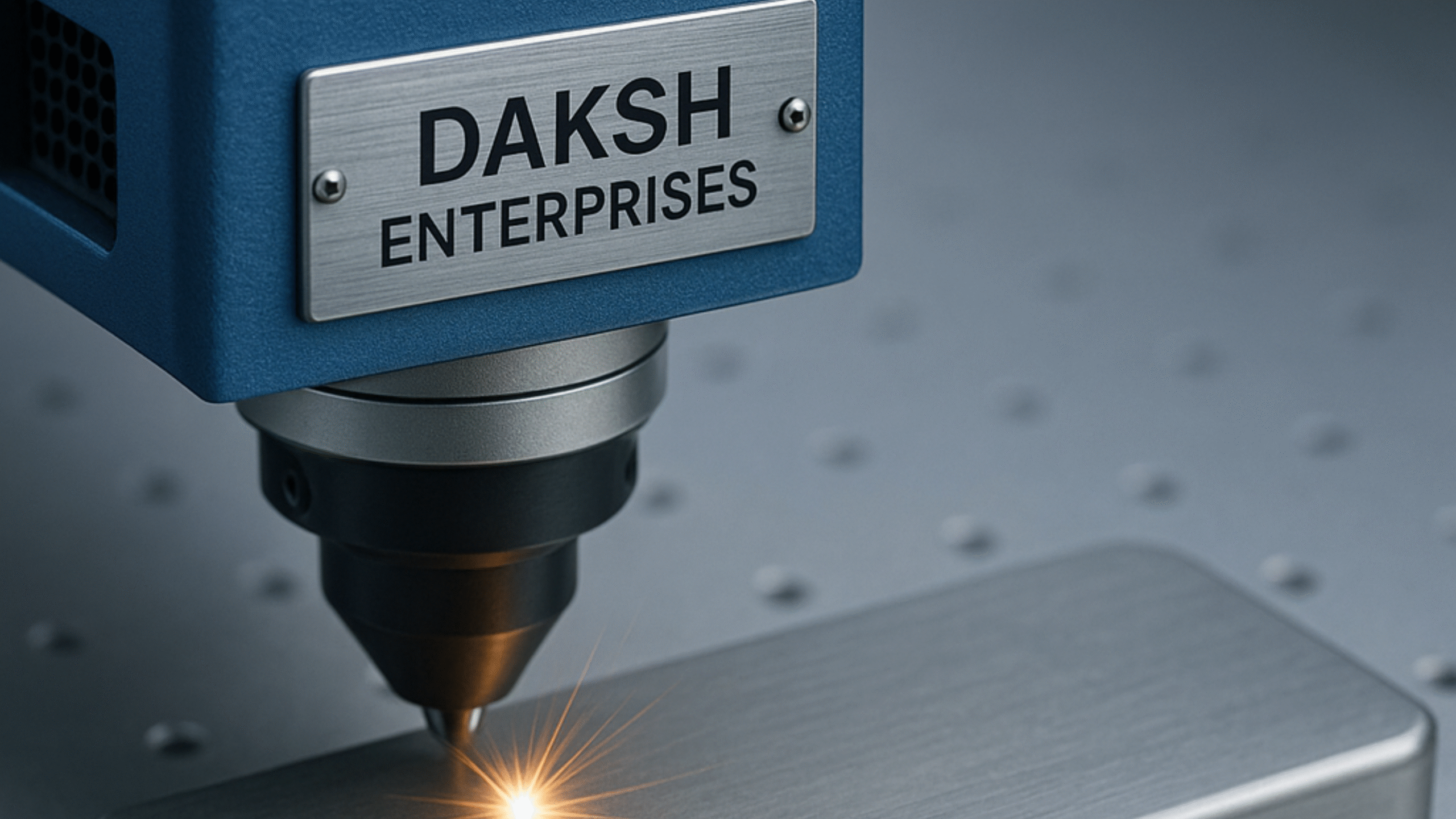

Industrial production is changing—and it is changing on the strength of laser marking technology. While industries need increased precision, faster processes, and cleaner processes, laser marking machines have become a necessary ingredient. Daksh Enterprises can observe the strength of this technology and consider itself fortunate to be a part of this revolution in manufacturing with its new laser marking technologies.

Laser marking is a method to create permanent marks on materials by employing a converging laser beam. Technology had been around for decades, but its rapid rate of development and application in recent years pushed it as a trendsetter among paradigms of next-generation production.

The Turning Point Towards Efficiency and Precision

With previous mark technologies—print, etch, or stamp—the were always certain trade-offs in regards to quality, life expectancy, or speed. Laser mark systems shatter all those fetters. They produce crisp, permanent marks that will never degrade or corrode over time. Regardless of the part numbers, logos, QR codes, or identification details, the finished product is accurate and permanent.

At Daksh Enterprises, we’ve seen how manufacturers across sectors—from automotive to electronics—are using laser marking to enhance product traceability and branding, all while improving production efficiency.

Limited, Yet Powerful Features

While laser marking machines offer a range of benefits, even the core features alone are enough to revolutionize operations:

Non-contact process – Reduces wear and tear, leading to longer machine life.

High-speed marking – Speeds up production without sacrificing quality.

Material compatibility – It is metal- and plastic- and other-material-compatible.

These basic yet solid features make laser marking an ideal choice for businesses that need to maximize their production plants.

Industry Evolution

As there is higher quality demand and traceability demand, laser marking is no longer an add-on but an essential. Organizations have to now provide sophisticated tracking on each piece and product. Laser marking allows them to give them clear, readable, and readable marks which fulfill customer as well as compliance requirements.

Additionally, when firms are in the process of converting to cleaner production, the environmentally friendly nature of laser marking—no ink, chemicals, or consumables—is an advantage.

Daksh Enterprises: Enabling Smarter Manufacturing

Right from its inception, Daksh Enterprises has focused on helping industries adopt smart, cost-effective solutions. With Mr. Surender Singh at the helm, we have built a strong foundation on quality, service, and faith. Our laser marking machines reflect this commitment in the form of long-lasting performance to cater to new-gen manufacturers’ needs.

Conclusion

Laser marking machines are not only marking surfaces, they are revolutionizing industries’ processes. With the capability to maximize accuracy, reduce wastage, and maximize speed, they are the hub of the future of manufacturing. At Daksh Enterprises, we are dedicated to bringing this future into being through quality service and innovative solutions.